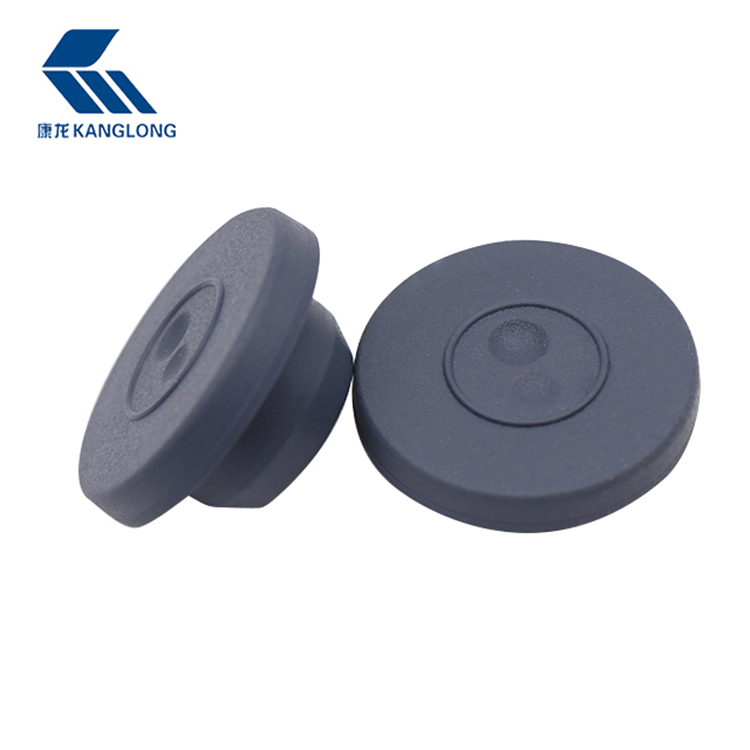

Pharmaceutical Rubber Stopper Price For Sale Maker in China

A Pharmaceutical Rubber Stopper for Injection is a small, flexible rubber disc used to seal vials or bottles containing injectable drugs. Its primary function is to protect the medication inside from contamination and to provide an airtight seal that ensures the stability of the drug. It is typically made from high-quality rubber, often a mixture of natural and synthetic materials, which offers the durability and resilience needed to maintain the integrity of the vial over time.

The Pharmaceutical Rubber Stopper for Injection is designed to fit snugly into the neck of the vial, preventing exposure to air, moisture, or other external contaminants that could compromise the drug's potency. Additionally, it allows for easy access to the medication via a syringe or needle, without needing to remove the stopper entirely.

Ensuring Sterility and Protection

One of the primary functions of the Pharmaceutical Rubber Stopper for Injection is to maintain the sterility of the injectable drug inside the vial. Injectable medications are particularly vulnerable to contamination, as they are directly introduced into the bloodstream and bypass the body's natural defense mechanisms. Therefore, it is essential to ensure that the drug remains free from microorganisms, dust, or any other contaminants.

The Pharmaceutical Rubber Stopper for Injection creates an effective barrier that protects the medication from external contamination, ensuring that the drug remains sterile until it is used. This is particularly important for drugs that are administered in hospitals or clinics, where maintaining a high level of cleanliness and safety is crucial to patient health.

Facilitating Safe and Accurate Dosage

Another important function of the Pharmaceutical Rubber Stopper for Injection is to facilitate the safe and accurate withdrawal of medication from the vial. When a syringe is used to draw up the medication, the rubber stopper allows for easy penetration by the needle. The stopper's design ensures that the needle can access the drug without causing damage to the vial or introducing any contaminants.

The Pharmaceutical Rubber Stopper for Injection is also engineered to create a seal that prevents any leakage of medication. This is particularly important for maintaining an accurate dosage, as leakage could medication wastage or incorrect dosages being administered. By ensuring that the syringe can withdraw the exact amount needed, the stopper plays a critical role in preventing dosing errors.

Preventing Drug Degradation

Certain injectable drugs are highly sensitive to air, light, or temperature changes. The Pharmaceutical Rubber Stopper for Injection helps preserve the drug's potency by providing a secure, airtight seal. This seal prevents air from entering the vial, which could oxidation or other chemical reactions that might degrade the drug. The stopper's ability to maintain this airtight environment helps prolong the shelf life of the medication.

In addition to protecting against air exposure, some Pharmaceutical Rubber Stopper for Injection designs also include coatings or treatments to provide additional protection against light or moisture. These features further help in maintaining the stability of sensitive drugs, such as vaccines, biologics, and other formulations that are prone to degradation.

English

English Español

Español

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)