Vacutainer rubber stoppers are essential components in the medical and laboratory fields, especially for applications involving blood collection and other biological samples. These stoppers are designed to ensure the integrity of the sample by creating an airtight seal that prevents contamination and leakage. As such, purchasing the right Vacutainer rubber stopper is crucial for ensuring the safety, reliability, and accuracy of medical and laboratory procedures.

The material used to manufacture Vacutainer rubber stoppers plays a critical role in their performance. These stoppers are typically made from high-quality rubber compounds, such as natural rubber, synthetic rubber, or a blend of both. The choice of material affects several properties of the stopper, including its flexibility, elasticity, chemical resistance, and ability to maintain a secure seal over time.

When purchasing Vacutainer rubber stoppers, it is essential to ensure that the material is compatible with the intended use. For example, in blood collection, the rubber must be non-reactive with blood and other biological substances to prevent contamination or interference with test results. Medical-grade materials, such as latex-free or non-toxic synthetic rubbers, are commonly used for this purpose to avoid any adverse reactions.

Additionally, the material should be durable enough to withstand various environmental conditions, such as temperature fluctuations and exposure to different chemicals or solvents. If the rubber stopper will be used in conditions, such as with samples that require refrigeration or freezing, it is important to ensure the material can handle these conditions without compromising its integrity.

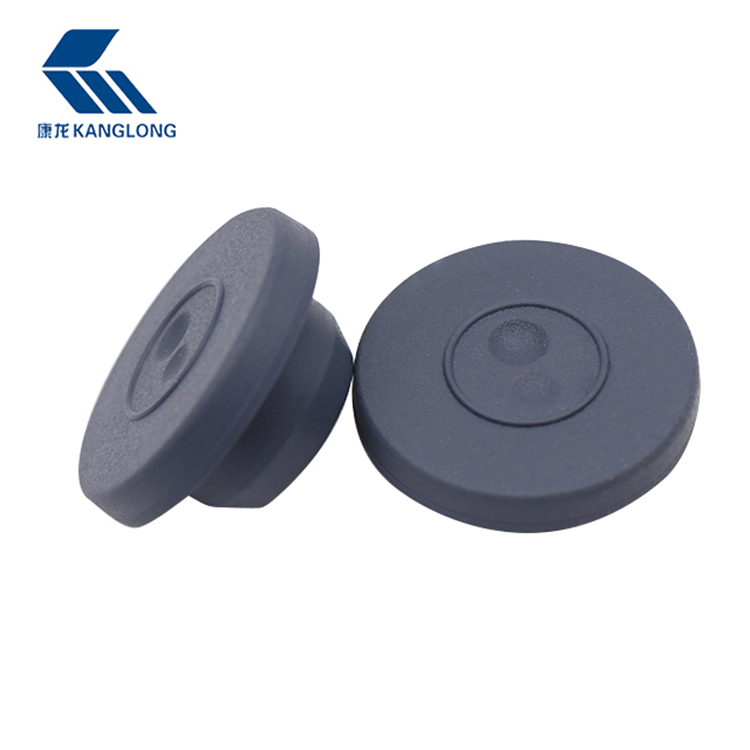

Another key consideration when purchasing Vacutainer rubber stoppers is the size and compatibility with the vials or tubes used for sample collection. Rubber stoppers come in various sizes to fit different types of containers, and choosing the correct size is vital to ensure an airtight seal. A stopper that is too large or too small will fail to provide the secure seal required, potentially to sample contamination or loss.

Before making a purchase, it is important to carefully check the specifications of the Vacutainer system, including the dimensions of the vial or tube and the type of stopper needed. Manufacturers often provide detailed guidelines on the appropriate stopper sizes for their products. Inaccurate sizing can result in the need for replacements or even compromise the integrity of the collected sample.

Some rubber stoppers also come with additional features, such as pre-pierced holes for needles or septa, which may be necessary for certain blood collection techniques. If this is required, buyers should ensure that the stoppers are designed with these additional features to accommodate the specific needs of the procedure.

Sterility is one of the important considerations when purchasing Vacutainer rubber stoppers, especially in medical and laboratory settings where contamination could inaccurate results or compromised patient safety. Many Vacutainer rubber stoppers are sterilized through processes such as gamma irradiation or ethylene oxide treatment to ensure they are free from any harmful microorganisms.

When purchasing these stoppers, it is important to verify that they are packaged in a sterile, sealed environment to maintain their sterility until use. Packaging plays a vital role in preventing contamination during storage and transportation. Many reputable suppliers will offer rubber stoppers that are individually sealed or packaged in bulk in sterile bags or boxes.

If the stoppers are being purchased for high-risk medical procedures, such as blood collection, it is advisable to confirm that they have been validated for sterility by recognized standards or regulatory bodies, such as the U.S. Food and Drug Administration (FDA) or the European Medicines Agency (EMA).

English

English Español

Español

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)