The healthcare and pharmaceutical industries rely heavily on precise, reliable, and high-quality components to ensure the safety and efficacy of medical products. One such essential component is the Medical Butyl Rubber Stopper, which plays a vital role in the containment and protection of injectable medications, especially in prefilled flush syringes. The production and launch of Medical Butyl Rubber Stoppers for these syringes involve several carefully orchestrated steps to meet stringent regulatory, safety, and quality standards.

1. Concept and Design Specifications

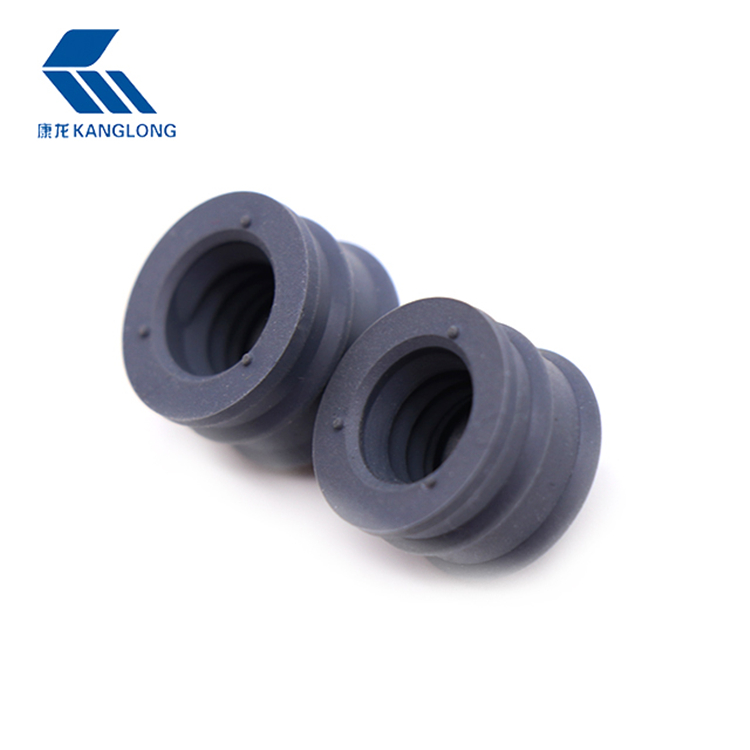

The step in the launch of Medical Butyl Rubber Stoppers for prefilled flush syringes begins with the development of the design and specifications. The specifications are based on the needs of the end users, which include both healthcare providers and patients. Key considerations at this stage include the size, shape, and material properties of the stopper, as well as its compatibility with the syringe.

Medical Butyl Rubber Stoppers must be designed to fit securely into the syringe barrel, ensuring a reliable seal to protect the medication from contaminants. Additionally, the stopper should be flexible enough to allow easy plunger movement while maintaining its integrity under pressure. During this phase, close attention is paid to the stopper's chemical resistance, sterilization compatibility, and mechanical properties, as well as its potential interaction with the pharmaceutical formulation.

2. Selection of Materials

The next critical step is the selection of appropriate materials. Medical Butyl Rubber is the material of choice for stoppers used in prefilled flush syringes due to its exceptional chemical resistance, low permeability to gases and liquids, and high resilience. During this phase, manufacturers evaluate the sourcing of high-quality butyl rubber that will meet the rigorous standards set for medical applications.

Material testing is a key part of this step. The rubber must be capable of withstanding sterilization processes, such as gamma radiation or ethylene oxide sterilization, without degrading. Moreover, the material must pass stringent biocompatibility testing to ensure that it does not pose any risk to patient health. Manufacturers also examine the rubber's resistance to extraction and leaching, as Medical Butyl Rubber Stoppers must not release harmful substances into the prefilled syringe contents.

3. Prototyping and Initial Testing

Once the design and materials are selected, the next step is to create prototypes of the Medical Butyl Rubber Stoppers. Prototyping allows for the testing of the stopper's fit, functionality, and compatibility with the prefilled flush syringe. During this stage, various tests are conducted to evaluate the stopper's mechanical properties, including compression, tear resistance, and elasticity. These tests ensure that the stopper maintains a secure seal during use while also allowing for easy plunger movement when administering medication.

Prototype testing also includes assessing the stopper's response to the chemicals and medications that it will come into contact with. For prefilled syringes, Medical Butyl Rubber Stoppers must be able to handle a wide range of pharmaceutical ingredients without reacting negatively or causing degradation of the drug.

4. Regulatory Approval and Compliance

After successful prototyping, the next step in the launch of Medical Butyl Rubber Stoppers for prefilled flush syringes is ensuring compliance with regulatory standards. This process typically involves submitting the product for review by regulatory bodies, such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), or other relevant authorities depending on the region.

To meet regulatory standards, manufacturers must demonstrate that the Medical Butyl Rubber Stoppers meet safety, performance, and quality criteria. This includes providing comprehensive documentation on the materials used, the manufacturing process, and the results of various tests, such as biocompatibility and extractables testing. The stoppers must also comply with Good Manufacturing Practices (GMP) to ensure that they are produced under controlled conditions and free from contaminants.

English

English Español

Español

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)